Essential Geomembrane Quality Tests and International Standards You Should Know

- Geomembrane

- Essential Geomembrane Quality Tests and International Standards You Should Know

Why Is Geomembrane Quality Testing Important?

Geomembranes are expected to perform for decades without failure. If one fails prematurely, it can lead to environmental disasters, costly remediation, and legal consequences. Quality tests help prevent that by verifying critical properties like:

- Durability and lifespan

- Resistance to chemical exposure

- Mechanical strength and flexibility

- Barrier performance against water vapor and UV light

By testing these properties before installation, project managers and engineers can be confident that the material will perform as expected over time.

Common Geomembrane Quality Tests

1. Tensile Strength Test

This test checks how much force a geomembrane can take before it breaks when pulled. It also reveals how much it stretches before tearing, which indicates ductility.

Purpose:

- Determine maximum tensile strength

- Measure elongation at break

- Analyze material behavior under load

Method:

A dumbbell-shaped sample is clamped in a Universal Testing Machine (UTM) and pulled until it breaks. The stress and strain values are recorded to assess elasticity and toughness.

2. Tear Resistance Test

This test measures the material’s ability to resist the spread of an existing tear — crucial for applications where sharp objects or rough terrain might damage the liner.

Purpose:

- Determine tear propagation resistance

- Understand toughness and energy absorption

Method:

A notched specimen is pulled in the UTM, and the force needed to spread the tear is measured.

3. Exposure Testing (UV, Chemical & Weathering Resistance)

Geomembranes, especially HDPE liners, must resist environmental conditions such as UV rays, temperature swings, and chemical exposure.

Types of Exposure Tests:

- Accelerated Weathering: Simulates years of exposure using UV lamps and heat chambers

- Natural Weathering: Samples are placed outdoors for long-term evaluation

- Chemical Immersion: Samples are submerged in chemicals to test resistance

Key Parameters:

- UV intensity

- Temperature cycles

- Humidity and moisture levels

- Chemical concentrations

4. Water Vapor Transmission Rate (WVTR) Test

This test measures how much moisture can pass through the geomembrane. It’s especially important for landfills, tunnels, and reservoirs where moisture control is essential.

Method:

A specimen is exposed to a humid environment on one side and a dry side on the other. The amount of vapor passing through is measured in g/m²/24h.

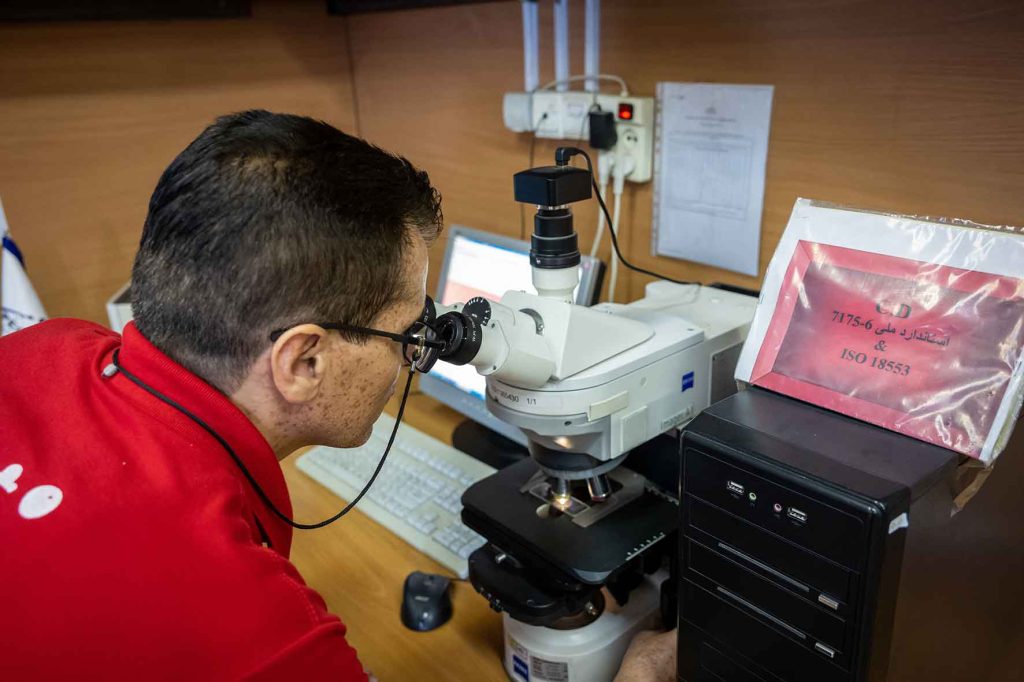

Global Standards for Geomembrane Testing

🔹 ISO Standards

- ISO 1421 – Tensile testing procedures

- ISO 13934 – Tear strength testing

- ISO 15105 – Water vapor transmission testing

- ISO 11358 – Puncture resistance testing

- ISO 11058 – Creep resistance

🔹 ASTM Standards

- ASTM D4595 – Wide-width tensile strength

- ASTM D624 – Tear resistance

- ASTM E96 – Water vapor transmission

- ASTM D543 – Chemical resistance

- ASTM G154 / G155 – Accelerated and natural weathering tests

🔹 Other Guidelines

- EN 13363 / EN 13364 – European standards for geosynthetics

- EPA / DOT / AWWA – Regulatory guidelines for landfill, transportation, and water use

Interpreting Geomembrane Test Results

Test results are only useful if interpreted correctly. Here’s what engineers typically look for:

- Thickness & Density: Ensures minimum material requirements

- Tensile Strength & Elongation: Indicates flexibility and load-bearing capacity

- Puncture Resistance: Prevents damage during installation or operation

- Seam Strength: Ensures welded joints don’t fail under stress

- Chemical Compatibility: Confirms material won’t degrade in hostile environments

Conclusion

Quality testing isn’t optional—it’s the foundation of safe, durable, and regulatory-compliant geomembrane installation. By following international standards and using a comprehensive testing approach, project stakeholders can ensure the geomembrane performs exactly as needed.

Source